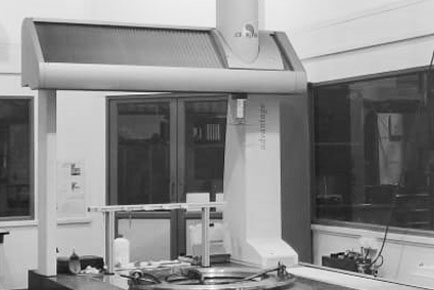

CMM (HEXAGON DEA GLOBAL ADVANTAGE)

The GLOBAL Advantage coordinate measuring machine (CMM) is optimised to measure large dimensional components with complex geometries in the automotive, aerospace and industrial machining industries. By utilising the versatility of the CMM, you can remove the bottleneck within the quality department and enable faster part setup for large complex parts.

The combination of high machine dynamics (speed and acceleration), optimised motion control algorithms, advanced software, thermal compensation and a wide variety of probe configurations make the GLOBAL Advantage ideal for the dimensional inspection of components with tight tolerances and complex geometries and free-form surfaces such as large valves, gears and gearbox components.